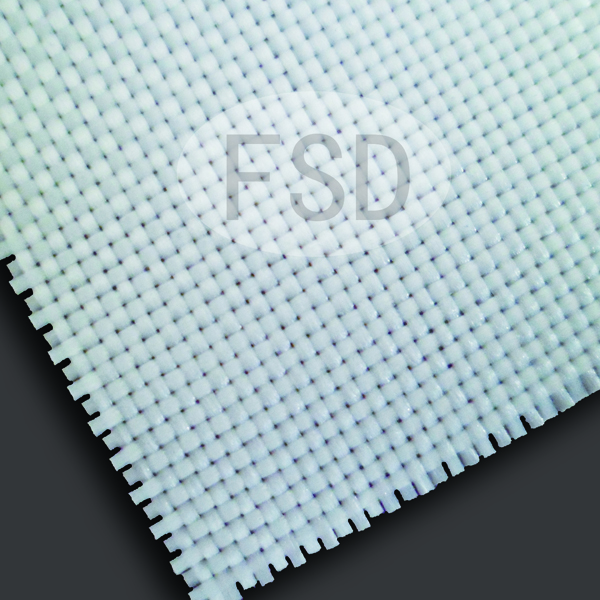

Fireproof fabric for automobile is made of ultra-fine high-strength composite fiber (silicate), using nano-infiltration composite technology, imported German technology and equipment, and processed through multiple strict processes. It is an excellent composite material that can meet multiple performance requirements at the same time, and is an ideal choice for the reinforcement and reinforcement of structural parts.

Main properties and characteristics of plastic Karen TM cloth:

● Light weight and high strength: Plastic Karen cloth TM has high rigidity and light weight, especially suitable for combination with various resins, rubber, plastics, rubber and plastic materials, etc. for reinforcement and reinforcement of the substrate. After compounding with these materials, a high-strength composite material is formed with high strength, impact resistance, good cushioning, good damping, corrosion resistance and aging resistance.

● Good chemical stability, resistant to various chemical corrosion.

● Good thermal stability, can work for a long time under high temperature (500 ℃).

● Good dimensional stability, not easy to deform, the size will not shrink or expand due to temperature, climate and other environmental changes.

● Good weather resistance, not easy to aging (anti-oxidation, anti-ultraviolet).

● Waterproof, non-hygroscopic (0.0% moisture regain).

● Good insulation (volume resistivity in 1013 ~ 1015Ω / cm).

The main purpose:

● Reinforcing and reinforcing base materials of automobile steel plate reinforcing materials, such as reinforcing linings, automotive damping plates, automotive rubber gaskets, automotive door panels, chassis, engine covers, and other structural parts, are widely used in trains and automobiles , Aircraft and other transportation.

● It is especially suitable for combination with various resins, rubbers, plastics, rubber and plastic materials, etc. for reinforcement and reinforcement of base materials. After compounding with these materials, a high-strength composite material is formed with high strength, impact resistance, good cushioning, good damping, corrosion resistance and aging resistance.

● Pressing various plates, such as various resin plates, epoxy plates, insulating plates, phenolic plates, copper clad plates, PTFE plates.

● As a decorative material overlay layer, the outer coating layer of the covering material.

● Insulation materials: electrical cabinets, electrical product components.

● Anti-corrosion materials: chemical-resistant boxes, tanks, pipes, bars, plates, etc.

● Reinforcement and reinforcement of structural parts such as buildings and bridges.

English

English ไทย

ไทย 한국어

한국어 日本語

日本語 svenska

svenska